DYMET

Technology & Equipment

DYMETTechnology & Equipment |

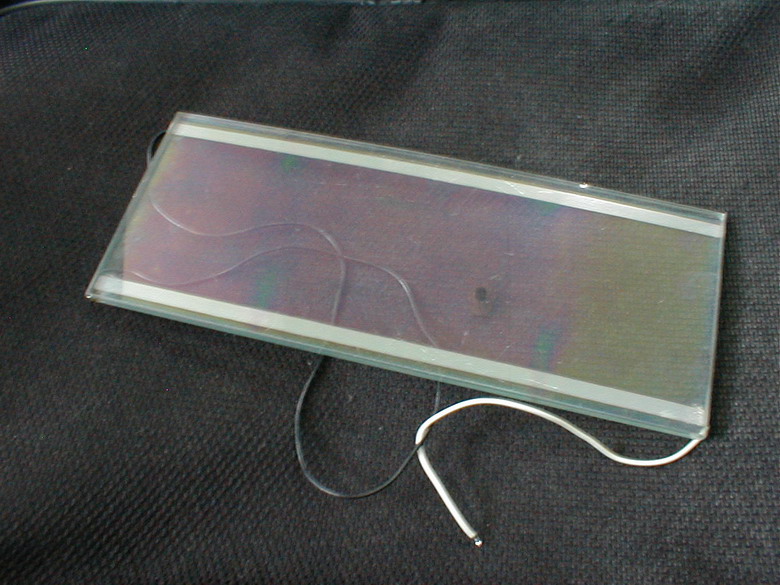

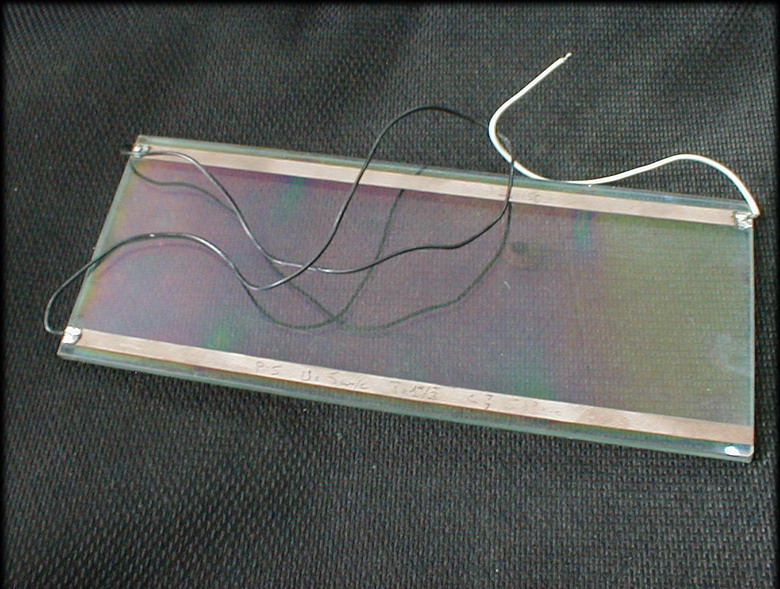

The temperature setting must be reduced for the coating spraying to the glass because of overheating causes the crack in the glass.

Do not try to create very thick coatings at the glass. The layer of thickness more then 0.5 mm may cause the glass damage under the coating.

Because of the high adhesion the coating does not delaminate but tear off with the piece of glass.

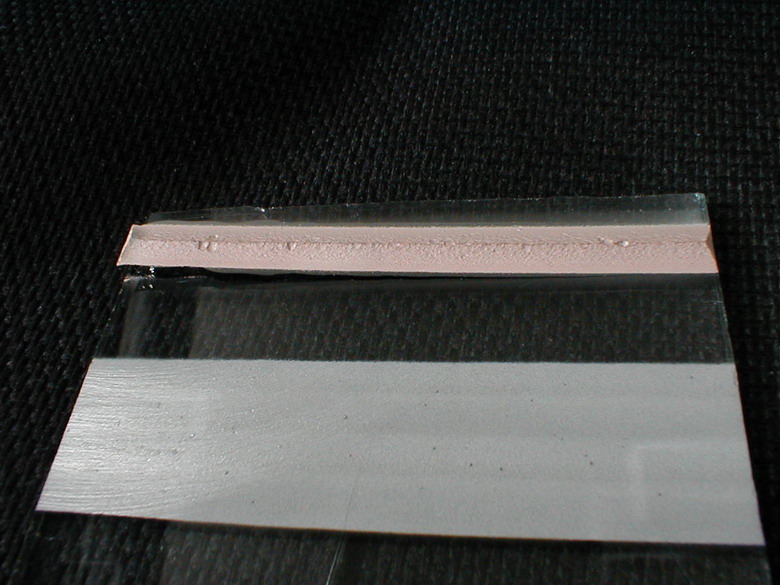

The correctly sprayed coating for soldering must have thickness not more then 0.5 mm and consists of the aluminum sublayer

and copper layer. The copper is soldered with low temperature solder.