|

The main rules for the DYMET application

|

|

- keep air pressure in operation above 5 bars to get proper jet acceleration and below 8 bars for stable powder to nozzle transportation;

- keep powder supply rate below 0.5 g/s to avoid jet overload;

- reduce temperature setting to improve coating quality, increase temperature setting to improve deposition efficiency;

- keep nozzle to substrate distance 5 - 15 mm, direct jet perpendicular to substrate surface.

|

|

Typical process parameters

|

|

- compressed air consumption 400 l/min;

- electric power consumption 3.5 kW;

- powder blend deposition efficiency 20 - 25 %;

- coating deposition rate 0.2 - 0.4 kg/hour.

|

|

Typical coating properties

|

|

- deposits to any metal substrate;

- bond strength 20 - 80 MPa;

- thickness from 0.002 mm up to 10 mm and more;

- tensile strength 30 - 80 MPa;

- porosity 1 - 7 %;

- Brinell hardness 60 - 160 MPa;

- elongation < 1 %.

|

|

Spraying thin coatings (thickness below 50 micrometers)

|

|

Thin coatings may be sprayed without any surface preparation. Powder blends contain enough ceramic inclusions to remove oil, rust and other surface contaminations just during the spraying.

Metal coatings at some substrates like ceramic require aluminum sublayer.

|

|

Spraying thick coatings (thickness above 50 micrometers)

|

|

Thick coatings may be sprayed without any surface preparation only to the soft metal substrates like aluminum alloys and copper. To avoid bond strength decrease at hard substrates like steel, cast iron and others prepare the surface by abrasive blasting.

Coatings at very hard materials like ceramic may require spraying aluminum sublayer first.

|

ANSWERS

|

Give advise on paremeters and powders recommended for the repair of :

- corroded or fretted gasket areas on cast iron cylinder block surfaces.

Requires machining flush with CBN or carbide tips after spraying.

- aluminium housings, corroded/fretted and machined after.

- steel shafts, repairing of worn seal areas. Surface turned in lathe to correct diameter after build up.

|

|

Most of answers may be found at http://dymet.info/en/app.html.

Usually copper or nickel are sprayed to cast iron. Aluminum and zinc are also possible in need.

Cast iron or other hard substrate (steel, bronze, etc.) must be abrasive blasted first. Use DYMET with K-00-04-16 abrasive powder to prepare surface. Usual sand blastind or another blastings process often are not quite satisfactory to produce roughness good enough.

Nickel (K32) or copper (K-01-01) or aluminum (K-80-13 or K-01-01) may be spayed to relatively smooth substrate surface without deep pitting or narrow slits.

In the case of deep pitting or narrow slits the defects are closed by powders with zinc addition like nikel-zinc (K714) or copper-zinc (K-01-11) or aluminum-zink (K-20-11).

In the case of spraying the coating by the powders with zinc addition the influence of strong acids or alkalies may be possible to the zinc inclusions. To prevent the influence of strong acids or alkalies thin nickel (K32) or copper (K-10-01) layer may be sprayed as the thin top layer to the already repared and polished areas at cast iron or steel part. Aluminum powder K-10-01 may be used for the same purpose at aluminum parts. Typically it is not necessary.

Any type of mashining of the coating is possible, but grinding or polishing are always better then milling or turning.

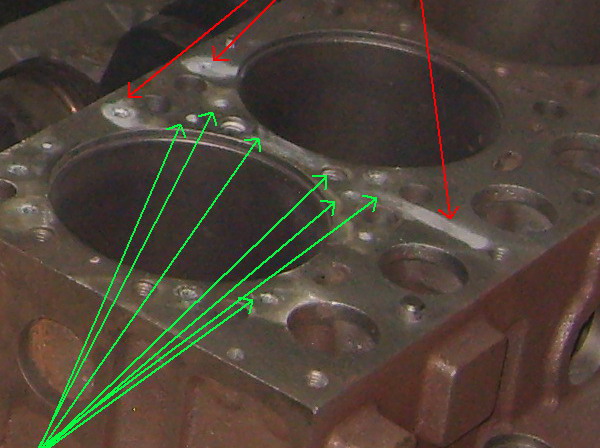

Spayed (red arrows) and sprayed and grinded (green arrows) areas differs in roughness and color.

To make the best coating for mashining use temperature setting "1" for the first deposited layer, change to "2", then "3", then "4". Lower settings are used for the better bond strength, upper settings for the better rate and economy. Dealing with nickel begin with "2" or "3", because of its hardness.

Spraying to aluminum parts does not require abrasive blasting. The use of the temperature setting "3" or "4" is possible from the very beginning.

Shafts journals surfaces should not be sprayed by DYMET. The coatings are not hard enough to provide good wear resistance. Only local defects elimination at the shaft journal is possible. Look http://dymet.info/en/app/auto33_.html. The powders and temperature settings are the same as described above for the cast iron.

|

|

The coating is brittle. Is there any possibility to make it more robust ?

|

|

.

Coating brittleness is determined by the large grain and cold-hardening of the material while spraying. .

Coating brittleness is determined by the large grain and cold-hardening of the material while spraying.

The coating flexibility may be improved by the heat treatment.

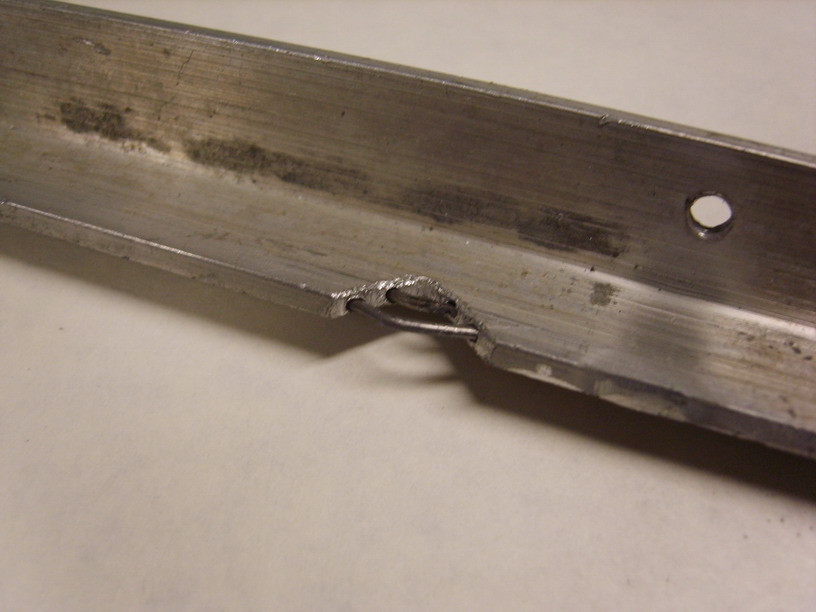

To strengthen the brittle builded up metal structure reinforcement may be used just as in the case of concrete reinforcement.

Look the example of the thin wall reinforcement.

|

|