DYMET

Technology & Equipment

DYMETTechnology & Equipment |

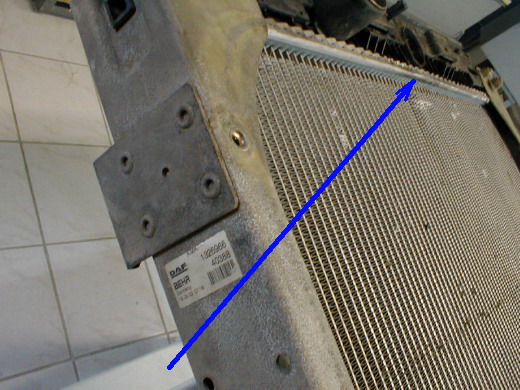

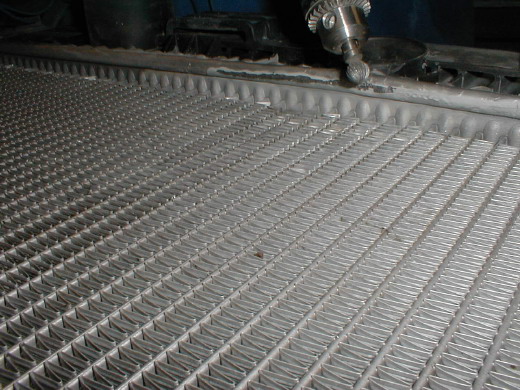

The edge of the engine radiator was broken by pliers while attempting to join it to expansion box.

The crack of about 80 mm length appeared just in the vicinity of plastic wall.

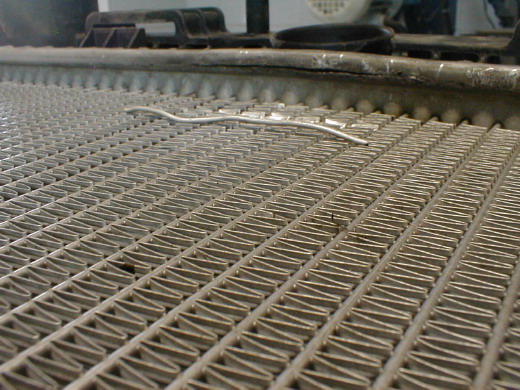

One may try to tighten the crack but the elasticity of plastic wall prevents the tightening. It is better to stick the crack by the soft aluminum wire.

Hummer out the wire and fix it to the crack.

Cut the prominent wire excess by mill. Soft wire will be tightly pressed into the crack under milling force.

Make sure that all large holes are filled by wire metal.

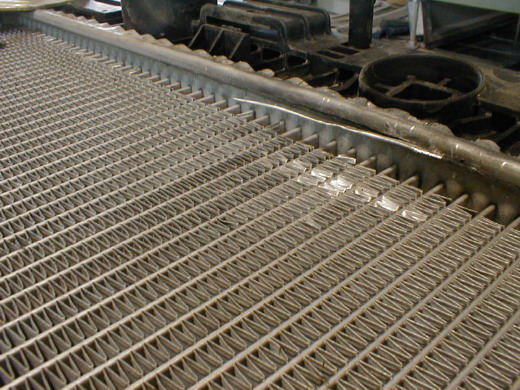

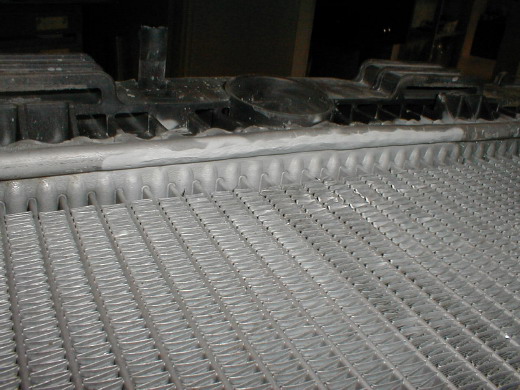

Spray powder K-20-11 at temperature setting “2” to avoid plastic overheating. At the positions of reach-through holes use setting “3”, but use frequent cooling pauses to keep plastic safe.

. Cut and smooth out the coating to assure that reach-through defects are eliminated by spraying.

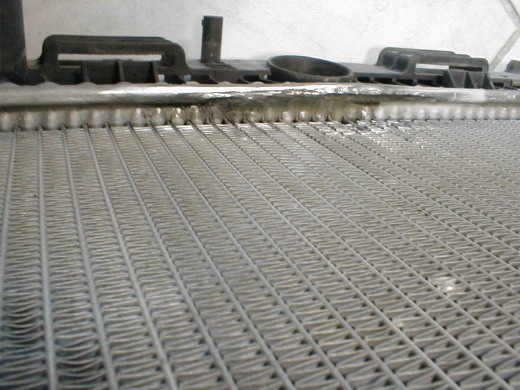

Finally spray coating at the temperature setting “2” for assured hermetic seal and reliable durability. The impermeability may be tested now.

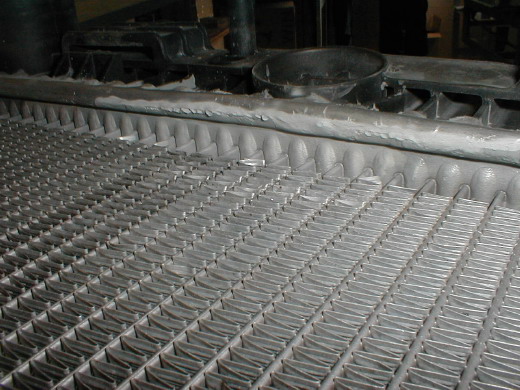

The leakage test reveals the microscopic pore channel exit at the very edge of the coating at inner wall. This leakage appeared because of coating was applied partially by on-the-miter spraying. The spraying at the very small angle to the substrate surface causes the formation of microscopic channels at the coating to substrate interface. The best approach will be to remove some foil, put the nozzle between the tubes and spray directly to the pin hole perpendicularly to the surface. But at the present case the leakage test was performed at another place and the exact position of the pin-hole was not accurately defined. So the spraying of wide coating line along the wall was applied. Paint of this part of coating was applied finally.