DYMET

Technology & Equipment

DYMETTechnology & Equipment |

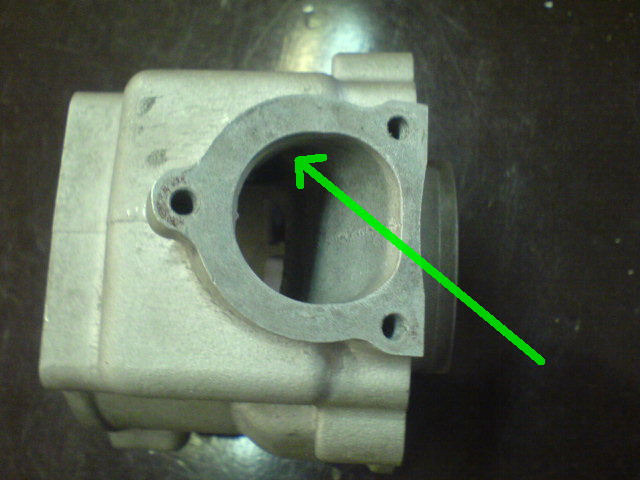

The engine part of sport cart is produced in Czeck Republic and modified in Italy,

but casting defects are revealed in Russia. In the thin wall through hole is observed.

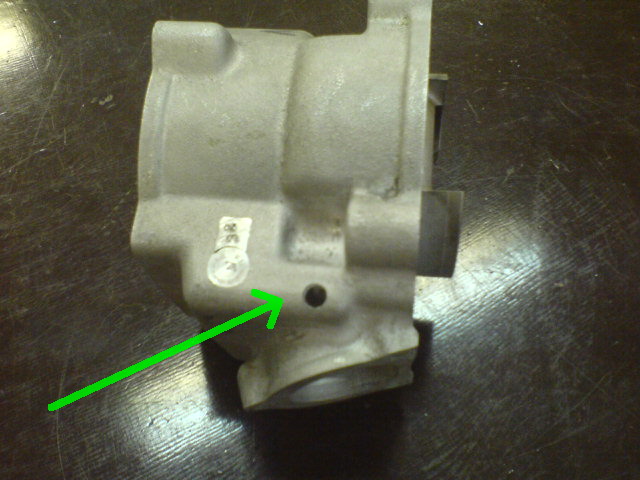

The nozzle may be positioned only at small angle, the wall thickness is miserable. The spraying is impossible in this situation.

The situation may be changed. Drill the hole in the wall opposite to the defect. Put the nozzle into the hole. The access to the defect is open.

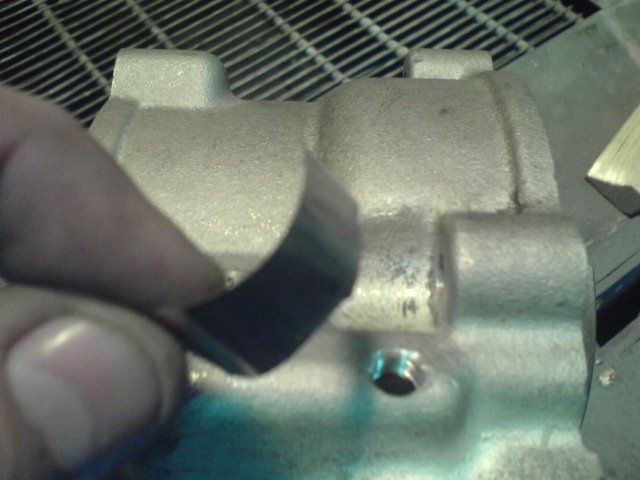

Put the foil to the rubber support

and tightly press to the defect wall.

Insert the nozzle into the drilled hole and spray to the foil closed defect. The coating of 1.5 - 2 mm thickness is sprayed by K-20-11 at temperature setting "3". Remove the foil after the spraying. Use hand mill and broach files to work up the sprayed metal.

Use tap borer to make a screw.

Turn screw into the wall.

Small facet is desired.

Spray over the screw by K-20-11. Remove the accessive metal.

Carting mechanics could find the defect place only by gray shades at the surface.

Would like to compare with surgical operation.

*AS*