DYMET

Technology & Equipment

DYMETTechnology & Equipment |

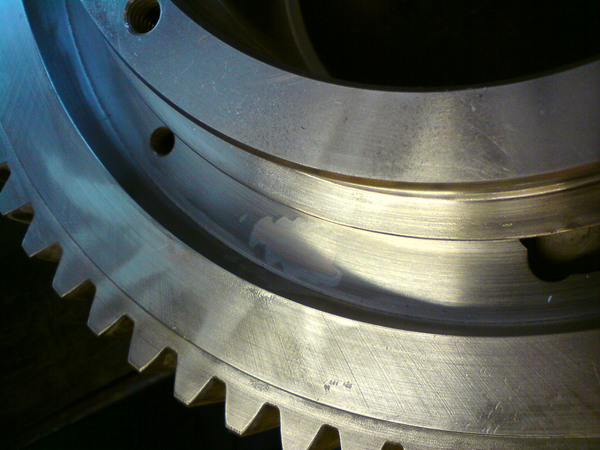

The dints appeared at cog-weel side face.

The dints prevent proper tool functioning.

The defects appeared because of the grip of sliding springs.

All dints were abrasive blasted and sprayed. The spraying at low angles requires excessive powder consumption.

The use of low pressure cold spray instead of welding prevented possible cog-weel teeth softening under the heating.

The part was turned at lathe after spraying.