DYMET

Technology & Equipment

DYMETTechnology & Equipment |

Sugar shredder stopped. The bearings jammed.

The bearing seats become worn

at both axle ends.

The wear is significant.

Blast both seats

by abrasive K-00-04-16.

Spray K-01-11 at temperature mode "1" or "2" first, continue at "3" or "4" then. Spray excessive thickness as machining allowance.

It turned out that more metal is required at this end. Well. Again abrasive, powder K-01-11 at "1" - "4".

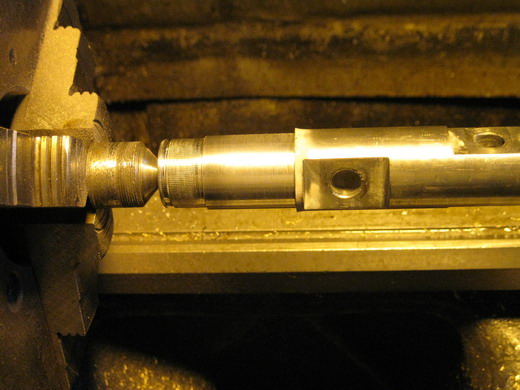

Put to lathe

and turn to exact size.

The coating has coarse-grained structure. Turn at high revolution rate and use minimal cutter stepover.

High quality is ensured by good tool.

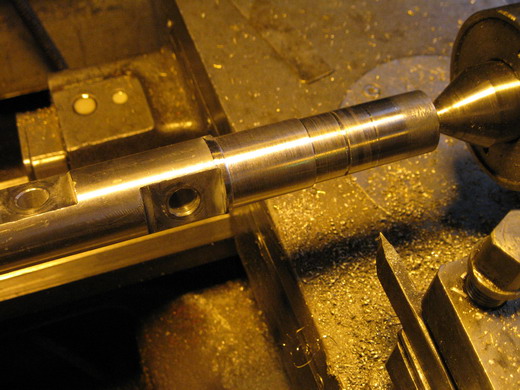

The seats are restored

at both axle ends.

The size meets the requrements again.